The simple act of pouring boiling water into a cup belies a complex history; the origins of which partly lie in a stretch of coastline between Mullion Cove and Pentreath on the Lizard peninsular and the subsequent manufacture of Soft Paste Porcelain.

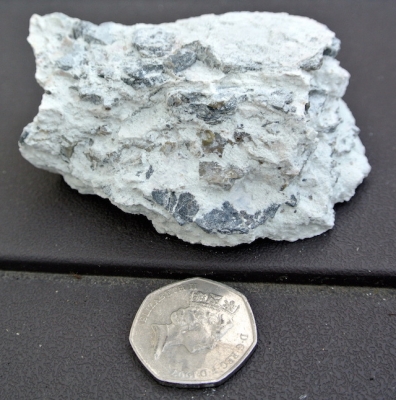

For it was from these Serpentine cliffs during the 1680’s that samples of soaprock were sent to the Royal Society in London to try to establish its characteristics and possible economic uses. By the 1720’s it was known that the high magnesium content of this metamorphic rock provided heat resistant properties for the production of porcelain. William Borlase in 1729 presented the work of Dr John Woodward who noted that soapy clay at Kynance and Gew Gaze was suitable for porcelain manufacture.

Ceramic porcelain prior to this was imported from China into many European Countries. However the growing trade in coffee, chocolate and later tea along with the increasing number who could afford to eat their food from porcelain plates and dishes meant the race was on to replicate the Chinese methods of porcelain production and so engage in a spreading and lucrative market.

In the 1730s new technology including accurate measurement of kiln temperatures and new, more skilful and reliable methods of storing the pots in the kiln to get an even temperature were developed.

In the 1730s new technology including accurate measurement of kiln temperatures and new, more skilful and reliable methods of storing the pots in the kiln to get an even temperature were developed.

Recent research has suggested that the first soaprock extracted for economic use was from Kynance Cove, and in the later 1740s new deposits were discovered at Gew Graze (Soapy Cove). The first known licenses to quarry soaprock were granted for this location in 1748 and the Pottery, run by Benjamin Lund was located at Bristol.

By 1752 the newly formed Worcester factory had taken over this pottery and the license for the site and began to extend the area it covered. By 1760 Worcester were the largest consumers of soaprock from quarries as far north as Mullion, as far south as Pentreath and inland at Daroose and Lizard Common. It was also extracted by Porcelain Factories at Vauxhall in London, Liverpool, Caughley and South Wales.

The quarry sites are still visible with a little practice on the cliffs and inland and another of these is Penruddock Quarry near Mullion Cove, now a site of managed wetland conservation and home to diverse species of plants and animals.

|

|

Soaprock changed the face of trade in the UK introducing a competitive industry. It was later superseded by the production of China Clay derived from granite and the production of Hard Paste Porcelain of which William Cookworthy played a part.

However William Cookworthy attempted to produce the original recipe for hard paste porcelain as used by the Chinese, using Cornish China Clay and China Stone, and was not able to produce merchantable quality products until 1768.

It all began with the quarrymen on the west Lizard Coast, in Cornwall and their work should be celebrated and not forgotten.

Acknowledgement and thanks to Bob Felce (BScHons)

Mullion

Published: July 2015

Author: Kathryn Conder